We aim to integrate the environmental impact of product manufacturing and use after sale (e.g., durability, recyclability, energy use) into design and buying guidelines.

Quality in Every Stitch

We believe in sourcing and constructing all our products to uphold our high-quality standards. We encourage our customers by providing information on the proper care which allows our products to last a long time in people’s lives versus ending up in a landfill.

We have a Global Quality Assurance and Supply Chain Team that applies stringent and industry-accepted quality assurance approaches. They also build-in operational, and customer experience data to achieve a proactive quality management strategy.

Our brands also believe that materials are a key component to making quality products that will last a long time. They continue to deepen their use of sustainable materials by adding more products made from certified-sustainably-grown fibers and certified-renewable wood sources, to reduce the use of conventional synthetic fibers.

Recycling & Upcycling

QVC Group’s support of recycling and upcycling is part of our contribution to the circular economy, and we are developing consistent recycling standards and partnerships across our supply chain. We believe in the creative reuse of materials through transforming by-products, waste materials, and useless, or unwanted products into new materials or products perceived to be of greater quality with environmental value.

Plastic Bank

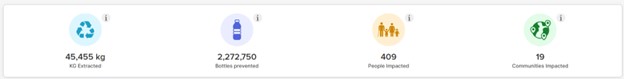

In 2024, we were thrilled to announce an exciting new partnership with Plastic Bank to support the collection and recycling of plastic from the environment!

Through this partnership with Plastic Bank, we gathered over 45 tonnes of plastic equal to 2,272,750 bottles which was recycled into Social Plastics, a recycled feedstock that is reprocessed and reintegrated into products and packaging for consumer goods. These results helped reduce the reliance on virgin plastics and significantly decrease greenhouse gas emissions associated with manufacturing.

By turning plastic into currency, we empowered the collection and exchange of discarded plastic. We believe that by working together with Plastic Bank and other partners, we can create a brighter and more sustainable future for everyone.

Reducing Textile Waste

We are also committed to supporting organizations that work to end commercial textile waste and maximize the value of unused fabric.

QVC US

QVC’s U.S. design studio partners with FABSCRAP, a 501c3 non-profit organization, to divert apparel and home textile samples from landfills. Located in New York City, FABSCRAP’s recycling service collects fabric excess from commercial brands, sorting material for reuse and downcycling. FABSCRAP is dedicated to generating groundbreaking industry waste-stream data and mobilizing stakeholders to tackle the waste-stream issue together. FABSCRAP partners with over 800 organizations, from luxury to contemporary brands, helping to manage textile waste sustainably and responsibly.

Garnet Hill

When designing and sourcing products, Garnet Hill carefully considers the materials they use and make ethical commitments to people and the environment, holding everything to the highest standards possible. With over 70% of products coming from renewable natural fibers, they consistently strive to do better and uphold their heritage as a natural fibers company.

Garnet Hill has expanded the use of organic cotton and linen. They also use LENZINGTM TENCELTM fibers and LENZINGTM ECOVEROTM viscose, both from sustainably-grown and certified-renewable wood sources, to reduce the use of conventional synthetic fibers.

Recycling and upcycling are areas of continued focus. The brand recently launched new recycled poly/spandex swim fabrication and converted all down alternative fills in our duvet inserts to be made from recycled polyester while maintaining the desired loft, washability, and durability – ensuring these recycled materials meet our high standards of quality and comfort. With not a fiber wasted, the recycled cashmere collection is made from remnants reclaimed as new garments are produced and their signature flannel program (their largest flannel sheeting program) uses WECYCLED® cotton yarns. The WECYCLED® process transforms unused, recycled yarns and cuttings from the manufacturing cycle into new, first-quality cotton fibers; the fibers are then incorporated with new, responsibly sourced fibers and woven into fabric. Garnet Hill even takes scraps from the manufacturing process of their percale sheeting program to craft 2 special hand stitched quilts for their line.

Sustainable Standards and Certifications

QVC Group is committed to using more certified sustainable fibers & fabrics due to their focus on durability, versatility and responsible production. Certifications also instill confidence that the materials are free from harmful substances, helping our customers make more informed purchases. They also show QVCG’s commitment to curating products responsibly to ensure that what we sell respects people and the planet.

To learn more, visit our Material Sourcing Transparency page.